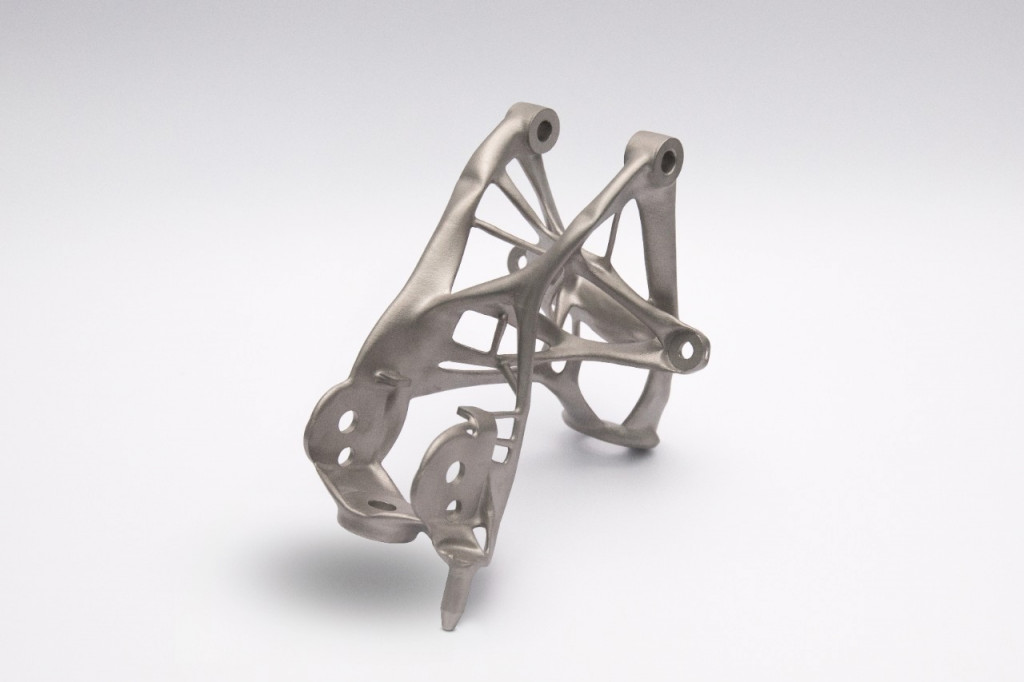

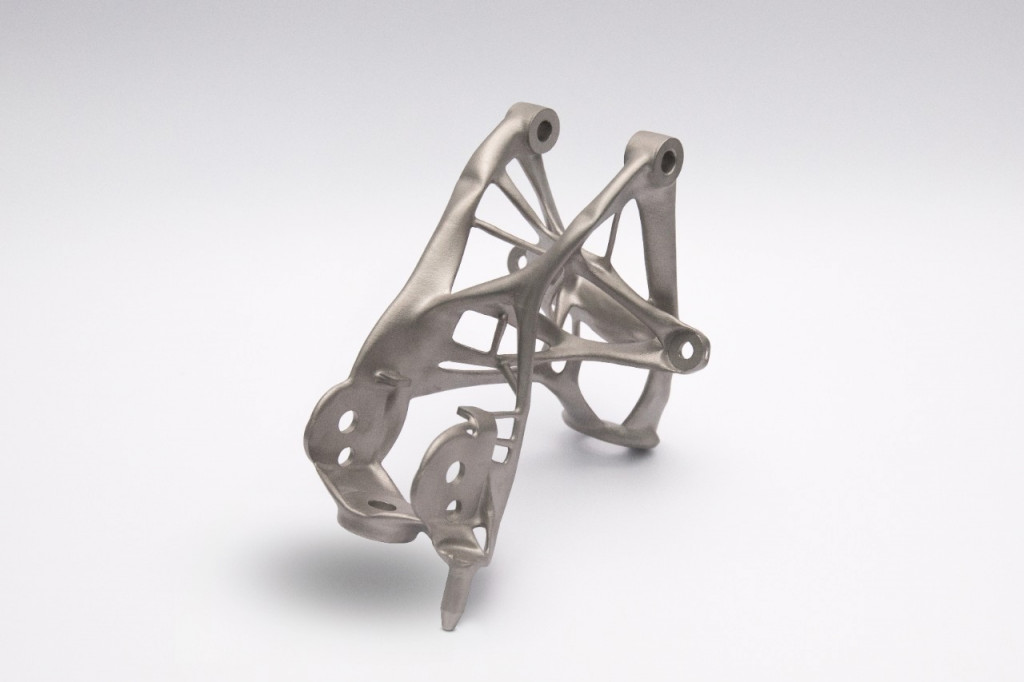

Future automotive components could look less like rigid pieces and more like organic shapes. General Motors announced on Thursday that the automaker has worked with Bay-area software company Autodesk to create a 3D-printed component to preview future manufacturing processes.

Khodrocar - The part is a seat bracket made from stainless steel. Compared to a traditional seat bracket, the 3D-printed part is 40 percent lighter and 20 percent stronger. Normally, the same part would involve eight separate components and several suppliers; the proof-of-concept part is one fluid piece.

The software technology behind the process is called generative design. It uses cloud computing and AI-based algorithms to envision hundreds of concepts based on parameters, goals, and manufacturing materials input by the user. The user can then tweak the final design for the project at hand.

GM envisions a future in which 3D printing takes over for countless manufacturing processes, and that will lead to lower costs and vehicle weights

"Generative design is the future of manufacturing, and GM is a pioneer in using it to lightweight their future vehicles,” said Scott Reese, Autodesk senior vice president for manufacturing and construction products. "Generative technologies fundamentally change how engineering work is done because the manufacturing process is built into design options from the start. GM engineers will be able to explore hundreds of ready-to-be-manufactured, high-performance design options faster than they were able to validate a single design the old way.”

Autodesk's technology could prove paramount in realizing GM's goal of profitable electric cars. Without extra components or numerous suppliers, the part-making process becomes simplified.

GM and Autodesk have forged a multi-year alliance to collaborate on 3D printing, generative design, and materials science.

Source: Motor Authority

The software technology behind the process is called generative design. It uses cloud computing and AI-based algorithms to envision hundreds of concepts based on parameters, goals, and manufacturing materials input by the user. The user can then tweak the final design for the project at hand.

GM envisions a future in which 3D printing takes over for countless manufacturing processes, and that will lead to lower costs and vehicle weights

"Generative design is the future of manufacturing, and GM is a pioneer in using it to lightweight their future vehicles,” said Scott Reese, Autodesk senior vice president for manufacturing and construction products. "Generative technologies fundamentally change how engineering work is done because the manufacturing process is built into design options from the start. GM engineers will be able to explore hundreds of ready-to-be-manufactured, high-performance design options faster than they were able to validate a single design the old way.”

Autodesk's technology could prove paramount in realizing GM's goal of profitable electric cars. Without extra components or numerous suppliers, the part-making process becomes simplified.

GM and Autodesk have forged a multi-year alliance to collaborate on 3D printing, generative design, and materials science.

Source: Motor Authority

Latest News